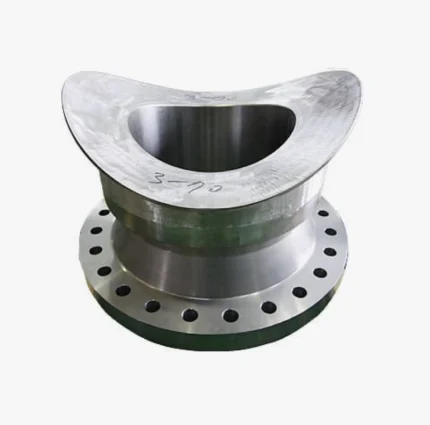

Forged Threaded Tee – Equal / Reducing

✔ Durable Forged Steel Body – Built for longevity

✔ Equal & Reducing Sizes – Versatile flow distribution

✔ Threaded Ends – Easy installation without welding

✔ High Pressure Rating – Suitable for critical systems

✔ Extensive Material Availability – Carbon, Stainless, Duplex, Alloys

✔ Manufactured to Global Standards – ASME B16.11 & BS 3799 compliant

Product successfully added to the Quote List

Forged Threaded Tee – Equal / Reducing

Forged Threaded Tee by Chero Piping is a high-strength, precision-engineered fitting designed for splitting or merging flow in industrial piping systems. Available in both equal and reducing types, this versatile tee adapts seamlessly to varied pipeline configurations in petrochemical plants, refineries, power stations, and offshore platforms. Manufactured to ASME B16.11 and BS 3799 standards, it ensures consistent quality, dimensional accuracy, and reliable performance. The precision threading allows for quick, leak-proof assembly without welding, making it ideal for high-pressure and high-temperature service. Forged from durable materials, these tees offer superior mechanical strength, excellent corrosion resistance, and extended service life in demanding environments. Whether used in aggressive fluids, steam, or gas systems, Chero’s forged threaded tees provide dependable, cost-effective flow control solutions. Suitable for compact installations and maintenance-friendly systems, they are a preferred choice in critical applications requiring structural integrity, long-term reliability and flanges.

| Brand |

Chero Piping |

|---|---|

| Industry |

Infrastructure |

| Type |

Threaded Tee – Equal / Reducing |

| Manufacturing Standards |

ASME B16.11, BS 3799 |

| Available Sizes |

1/8" to 4" |

| Pressure Ratings |

2000#, 3000#, 6000# |

| Material Options |

Carbon Steel, Stainless Steel, Duplex, Super Duplex, Nickel Alloys |

| End Connection Type |

Threaded (NPT/BSPT) |

| Temperature Resistance |

High |

| Design Benefits |

Versatile, reusable, no welding required |